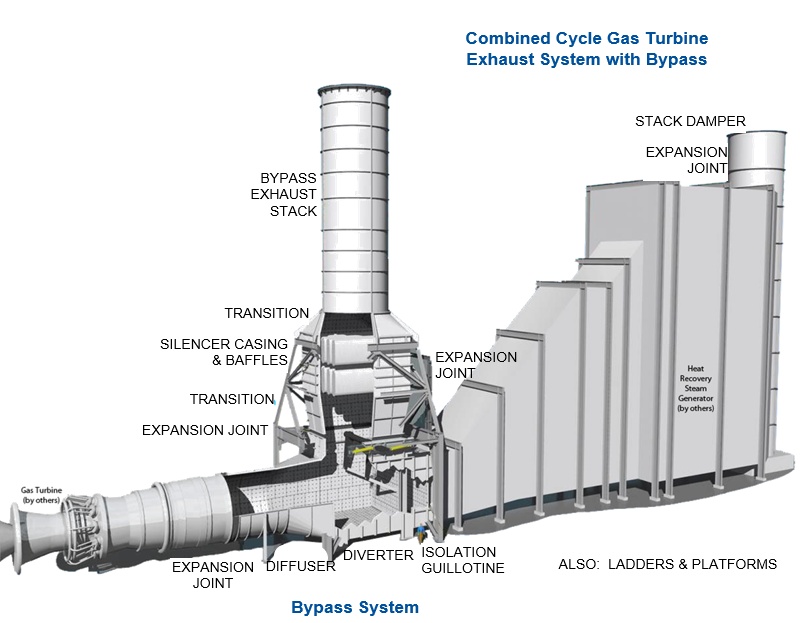

Exhaust systems are necessary to guide the exhaust flue gases of the gas turbine into the atmosphere. In simple cycle installations, the exhaust flue gas will be leaving the gas turbine through the diffuser into the stack.

In combined cycle plants, the hot exhaust gas will be used in the heat recovery steam generators, to operate additional steam turbines in order to improve the total efficiency of the power plant. In many plants, a diverter damper is installed between gas turbine and heat recovery steam generator. This enables the operator to run the plant in combined cycle mode or in simple cycle mode, in case the boiler has to be maintained

The use of exhaust systems behind the gas turbines is mandatory as the exhaust flue gases amount to temperature between 400°C and 650°C. The noise emission behind the gas turbines is also a major health risk and needs to be reduced by noise reduction measures. The most frequent measure is the use of absorbing silencer splitters in the bypass stack.

Protorque Equipment Pvt. Ltd. with technical collaboration with STEJASA, carries out designing and manufacturing of the whole exhaust system, starting at the exhaust flange of the gas turbine up to the connecting flange on the heat recovery steam generator, basically consisting of exhaust diffuser, diverter damper and a bypass stack with silencer.